When it comes to versatile materials in the world of manufacturing, 4x8 ABS Sheet Manufacturers in Gujarat stand out as a top choice. Their durability, affordability, and adaptability make them a favorite across various industries. In this comprehensive guide, we delve into everything you need to know about ABS plastic sheets, from their composition and properties to common applications and frequently asked questions.

What are ABS Plastic Sheets?

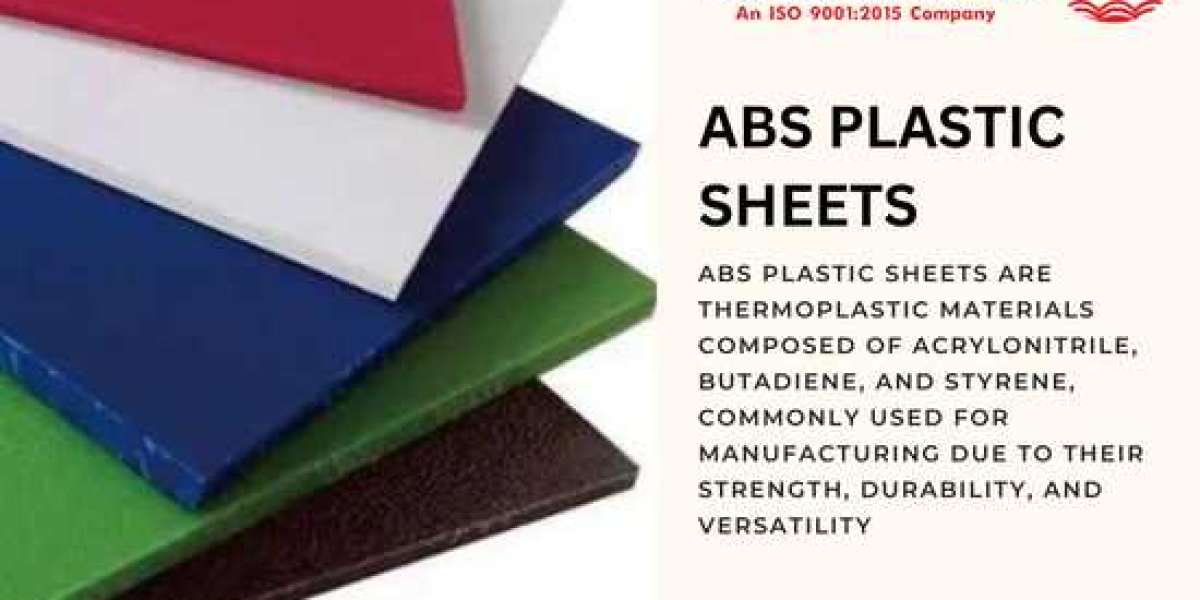

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its strength and rigidity. ABS plastic sheets are formed by extruding or molding ABS resin into flat, thin panels. These sheets are available in various thicknesses and colors, offering versatility for a wide range of applications.

Properties of ABS Plastic Sheets

Strength and Durability: 4x8 Sheet of ABS Plastic Exporters in Ahmedabad are renowned for their high impact resistance, making them suitable for applications where strength and durability are essential.

Heat Resistance: ABS sheets exhibit good heat resistance, maintaining their structural integrity at temperatures ranging from -20°C to 80°C (-4°F to 176°F).

Chemical Resistance: ABS plastic is resistant to many chemicals, oils, and greases, enhancing its suitability for industrial applications.

Ease of Processing: ABS plastic sheets are easy to shape, cut, and mold, allowing for intricate designs and customization.

Surface Finish: These sheets can be finished to achieve different surface textures, including gloss, matte, and textured finishes, catering to diverse aesthetic preferences.

Applications of ABS Plastic Sheets

Automotive Industry: ABS Manufacturers in India are commonly used in automotive interiors, such as dashboard panels, trim components, and interior linings, due to their durability and heat resistance.

Consumer Electronics: ABS plastic sheets find extensive use in manufacturing consumer electronic devices, including computer cases, keyboards, and housings for appliances, thanks to their electrical insulation properties and ease of customization.

Medical Equipment: ABS sheets are utilized in the production of medical equipment and devices, such as housings for diagnostic devices, surgical instruments, and laboratory equipment, owing to their biocompatibility and sterilizability.

Point of Sale Displays: ABS plastic sheets are popular for creating attractive and durable point of sale displays and signage in retail environments, offering a cost-effective solution for branding and marketing purposes.

Prototyping and Modeling: ABS sheets are favored for rapid prototyping and modeling in product design and development processes, allowing designers to create functional prototypes with ease.

Conclusion

ABS plastic sheets offer a winning combination of strength, durability, and versatility, making them indispensable in numerous industries and applications. Whether you're in automotive manufacturing, consumer electronics, healthcare, or retail, ABS sheets provide a reliable solution for your material needs. With their excellent properties and ease of processing, ABS plastic sheets continue to be a preferred choice for engineers, designers, and manufacturers worldwide.

Frequently Asked Questions (FAQs)

- Are ABS plastic sheets recyclable?

ABS plastic sheets are recyclable, but the recycling process can be challenging due to their complex composition. However, advancements in recycling technologies are making it increasingly feasible to recycle ABS plastic efficiently.

- Can ABS plastic sheets be painted?

Yes, ABS plastic sheets can be painted using various methods, including spray painting, brush painting, or immersion painting. However, proper surface preparation is crucial to ensure adhesion and longevity of the paint.

- Are ABS plastic sheets food-safe?

ABS plastic is generally considered safe for food contact, provided it is manufactured and handled according to relevant regulations and standards. However, it's essential to verify the specific grade of ABS and any applicable certifications for food-safe applications.

- How do I clean ABS plastic sheets?

ABS plastic sheets can be cleaned using mild soap and water or a solution of water and vinegar. Avoid using abrasive cleaners or solvents that may damage the surface. For stubborn stains, gentle scrubbing with a soft cloth or sponge is recommended.

- What sizes and thicknesses are ABS plastic sheets available in?

ABS plastic sheets come in various sizes and thicknesses to suit different applications. Standard sheet sizes typically range from 4 feet by 8 feet to 5 feet by 10 feet, with thicknesses ranging from 0.030 inches to 0.500 inches. Custom sizes and thicknesses may also be available upon request.