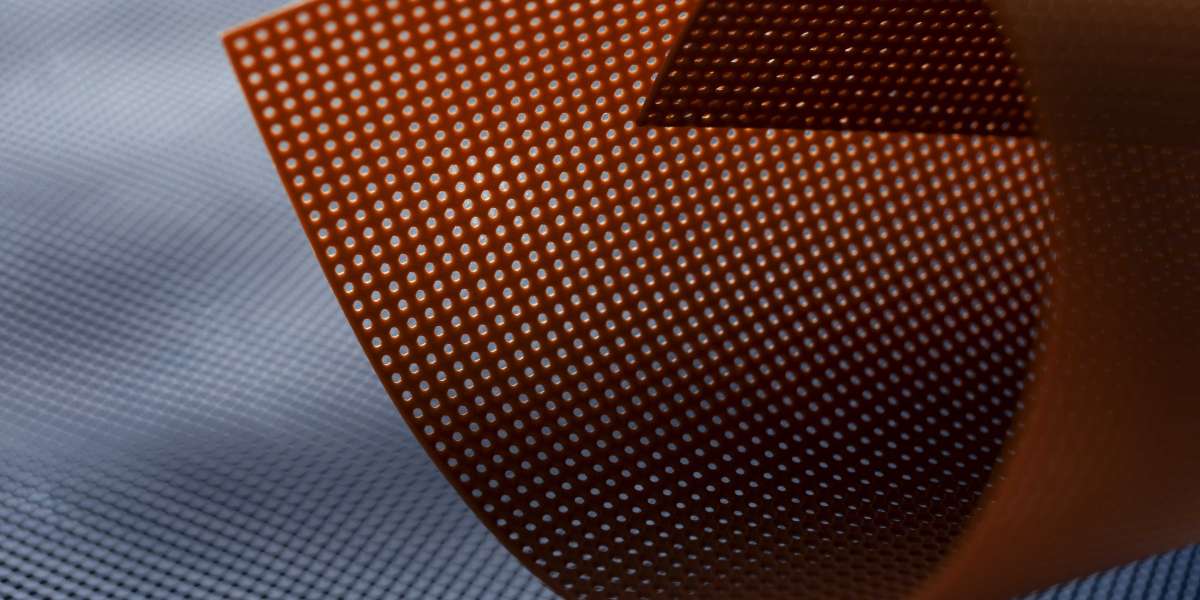

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile material known for its durability and wide range of applications. As a synthetic rubber, EPDM is prized for its resistance to environmental factors, making it an excellent choice for many industries. This article explores the key benefits of EPDM and its common uses, highlighting why it’s a popular choice in various applications.

Benefits of EPDM Rubber

One of the most significant advantages of EPDM is its exceptional weather resistance. Unlike natural rubber, EPDM can withstand prolonged exposure to ultraviolet (UV) light, ozone, and extreme temperatures. This makes it ideal for outdoor applications where materials are subject to harsh environmental conditions. EPDM rubber remains flexible and retains its properties even after extended exposure to sunlight and varying temperatures, which is crucial for outdoor products.

Another benefit of EPDM is its excellent resistance to water and steam. It does not swell or degrade when in contact with water, which makes it suitable for sealing applications in plumbing and automotive industries. Additionally, EPDM’s resistance to steam ensures that it can perform well in high-temperature environments, such as those found in industrial machinery.

EPDM also offers impressive chemical resistance. While it does not perform well with petroleum-based products, it resists a wide range of chemicals, including acids and alkalis. This property is particularly valuable in chemical processing plants and laboratories where exposure to harsh chemicals is common.

Common Applications of EPDM Rubber

Due to its unique properties, EPDM rubber is used in various applications across different industries. In the automotive sector, EPDM is used in weather stripping, seals, and gaskets. These components benefit from EPDM’s resistance to weathering and temperature fluctuations, ensuring that vehicles remain protected from the elements and maintain their performance over time.

In the construction industry, EPDM is commonly used for roofing membranes, making it a top choice for roof waterproofing. The material’s durability and resistance to UV light make it ideal for roofing systems that need to withstand the elements for extended periods. EPDM roofing membranes are known for their longevity and low maintenance requirements, contributing to effective waterproofing and overall protection.

EPDM is also utilized in the manufacturing of various seals and gaskets. Its flexibility and resilience make it a reliable material for creating seals that need to perform under varying conditions. These seals are crucial in preventing leaks and ensuring the proper functioning of machinery and equipment.

In addition to these uses, EPDM is employed in the production of garden hoses and conveyor belts. Its flexibility and resistance to wear and tear make it suitable for these applications, where it needs to endure continuous use and exposure to different conditions.

Conclusion

EPDM rubber is a highly versatile material with numerous benefits and applications. Its resistance to environmental factors, water, steam, and a wide range of chemicals makes it a valuable choice in many industries. Whether used in automotive parts, roofing systems for roof waterproofing, or seals and hoses, EPDM’s durability and performance contribute to its popularity as a reliable material. Understanding the benefits and applications of EPDM can help in selecting the right materials for various projects, ensuring durability and efficiency in their performance.